Types of Industrial Blowers and Their Applications

Every industrial application that requires moving air, gasses, or particles through a system relies on the right type of blower to get the job done efficiently. Whether it’s drying materials, ventilating large spaces, or controlling dust, choosing the correct blower type is essential to meeting the demands of each unique process. The selection often depends on specific factors like air volume, pressure requirements, and the environment in which the blower operates.

With several types of industrial blowers available, each is designed to support specific operational needs. Here’s a closer look at the main types and where they work best.

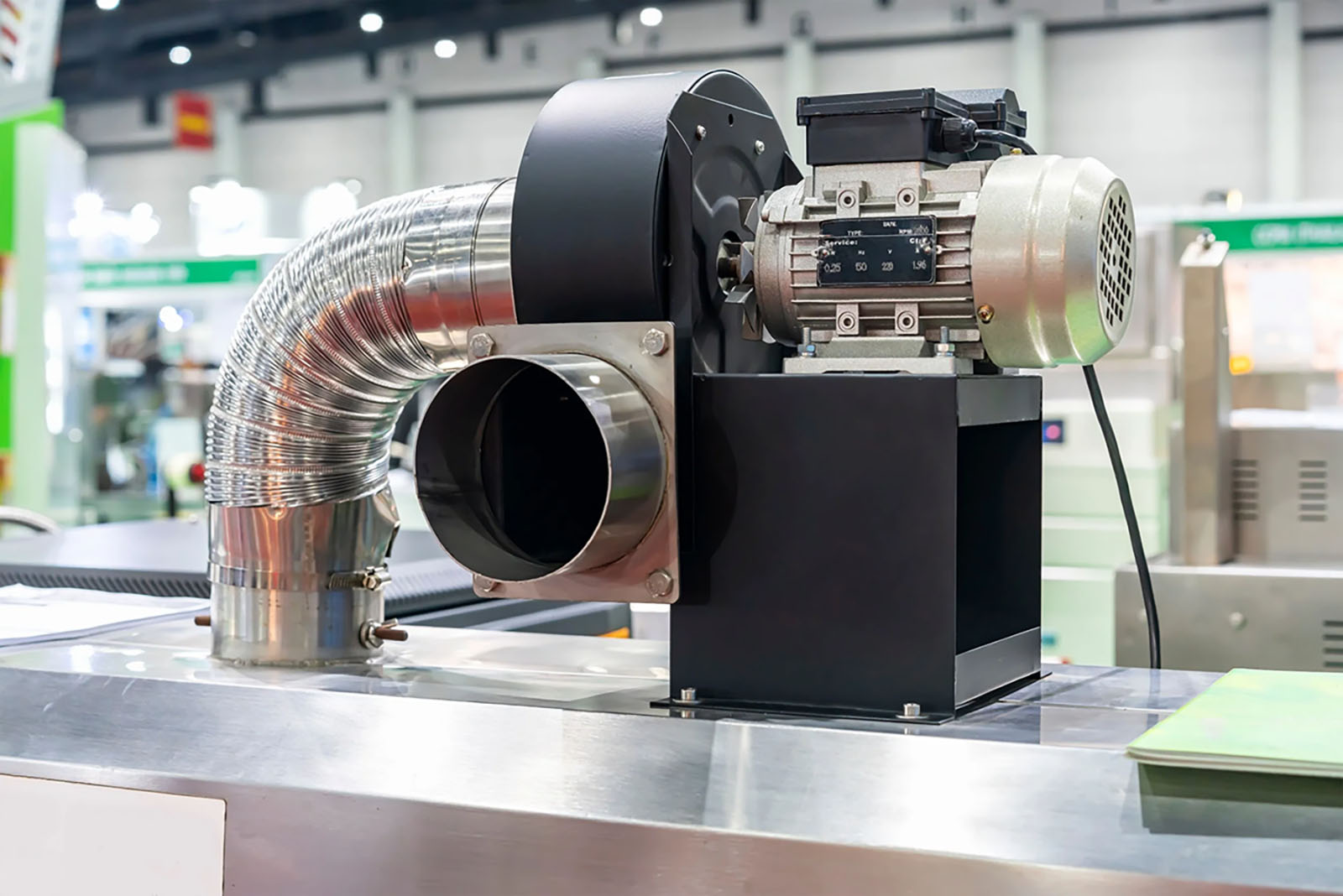

Centrifugal Blowers

How They Work:

Centrifugal blowers, also called “radial blowers,” create a powerful airflow by using an impeller that spins to pull air in and push it outward. An impeller is a rotating, fan-like component that moves air or fluid by creating centrifugal force. As it spins, it pushes air or fluid outward, increasing its speed and pressure to drive it through the system. This design allows centrifugal blowers to produce high-pressure airflow that's ideal for applications that require steady, strong air movement.

Applications:

Centrifugal blowers are widely used in ventilation, drying, and dust collection systems found in manufacturing facilities.Centrifugal blower also perform reliably for tasks like removing fumes or dust in environments such as metalworking or chemical processing. And they're common in large-scale cooling systems, where consistent airflow is necessary to maintain temperatures and prevent equipment overheating.

Key Benefits:

These blowers provide stable and powerful airflow, making them versatile and effective in challenging environments. Their durability and capacity to handle high pressures make them a popular choice in industries that need continuous, robust airflow.

Axial Blowers

How They Work:

Axial blowers move air in a straight path that's parallel to the blower’s axis, much like a propeller on an airplane. Air enters from one side of the blower, passes along the rotating blades, and exits on the opposite side, creating a high-volume, low-pressure flow. Because of their straightforward design, axial blowers are energy-efficient and work well in systems where steady airflow is more important than high pressure, such as HVAC systems, warehouses, tunnels, and agricultural ventilation.

Applications:

Axial blowers are most often found in ventilation systems where maintaining fresh air flow is the goal, such as in large warehouses, greenhouses, or tunnels. In industrial spaces where fumes or hot air need to be removed quickly, axial blowers are often the answer. They’re also common in HVAC systems for climate control in large spaces.

Key Benefits:

Axial blowers are energy-efficient and effective for moving large volumes of air over considerable distances. Their straightforward design makes them easy to install and maintain and they consume less energy compared to high-pressure blowers.

Positive Displacement Blowers

How They Work:

Positive displacement blowers use rotating lobes or gears to trap air and force it through a system. Unlike centrifugal or axial blowers, positive displacement blowers don’t rely on impellers. Instead, they create consistent airflow by “displacing” or moving pockets of air at steady intervals, resulting in the controlled and powerful movement of air.

Applications:

Positive displacement blowers are highly effective in applications where precise, steady airflow is required under constant pressure. Wastewater treatment plants use these blowers to aerate water and support biological processes that break down contaminants. They’re also used in pneumatic conveying systems to transport materials like grains or powders, where steady air pressure is crucial to keep materials moving smoothly.

Key Benefits:

Positive displacement blowers are valued for their ability to provide consistent airflow at fixed pressures, regardless of system resistance. Their controlled air movement makes them ideal for precise applications where a steady, reliable flow is essential.

Regenerative Blowers

How They Work:

Regenerative blowers, also known as side channel blowers, work by trapping air between the blades of a rotating impeller and moving it in a spiral motion within the blower housing. This process “regenerates” or reuses the same air particles multiple times to build up pressure gradually. Regenerative blowers don’t reach the high pressures or high volumes of axial and centrifugal models, but they do create moderate pressure with a steady flow.

Applications:

Regenerative blowers are common in applications that require clean, dry air without contaminants. You'll find them in medical and laboratory settings where sanitary airflow is needed. They’re also used in aquaculture for aeration to help maintain oxygen levels in fish tanks or ponds. Additionally, regenerative blowers perform well in industrial drying processes, where moisture control is key.

Key Benefits:

Their ability to generate continuous, clean airflow makes regenerative blowers the preferred choice for applications where air purity matters. Additionally, they have fewer moving parts compared to other blowers, so they are low-maintenance and long-lasting, which makes them appealing for continuous-use applications.

High-Speed Turbo Blowers

How They Work:

High-speed turbo blowers use advanced, highly engineered impeller designs and high-speed motors to generate rapid airflow at very high pressures. These blowers are capable of providing exceptional air speeds, often supported by integrated control systems that monitor performance and adjust as needed.

Applications:

High-speed turbo blowers are used in applications requiring rapid, intense airflow, such as aeration in wastewater treatment facilities. They’re also used in industrial cooling systems where large volumes of air need to be directed over hot surfaces to quickly lower temperatures. Their ability to generate high-pressure airflow in short bursts makes them ideal for processes where time-sensitive cooling or drying is required.

Key Benefits:

Turbo blowers combine high performance with energy efficiency, thanks to their advanced engineering and control features. Their ability to maintain powerful airflow without excessive energy consumption makes them a strong choice for high-demand industrial applications.

Which Blower Do You Need?

Selecting the right industrial blower can make all the difference in how well your system operates. Each type has strengths that suit different tasks, whether it’s high-pressure airflow for dust control or steady, reliable movement for ventilation. Understanding these differences helps you choose equipment that enhances performance, supports energy efficiency, and reduces costs.

When it comes to making informed decisions, having expert guidance makes all the difference. For personalized advice, answers to your blower questions, and professional product selection, connect with the team at Chandler Vac. Chandler VAC has over four decades of experience connecting customers with high-quality pumps and blowers from leading manufacturers such as Jurop and Battinoni.- Choosing a selection results in a full page refresh.

!